The Engines

ADEPT Airmotive identified the opportunity to satisfy the need for modern, fuel-efficient engines to power existing and new light aircraft. We manufacture a range of General Aviation engines specifically developed to address our customer requirements…

Our competitive advantage lies in considerable weight saving, robust and compact design (allowing installation into a wide range of airframes, ranging from utility to competition aircraft, including rotorwing applications), superior engine management, fuel efficiency and reduced maintenance costs. Both tractor and pusher applications are available.

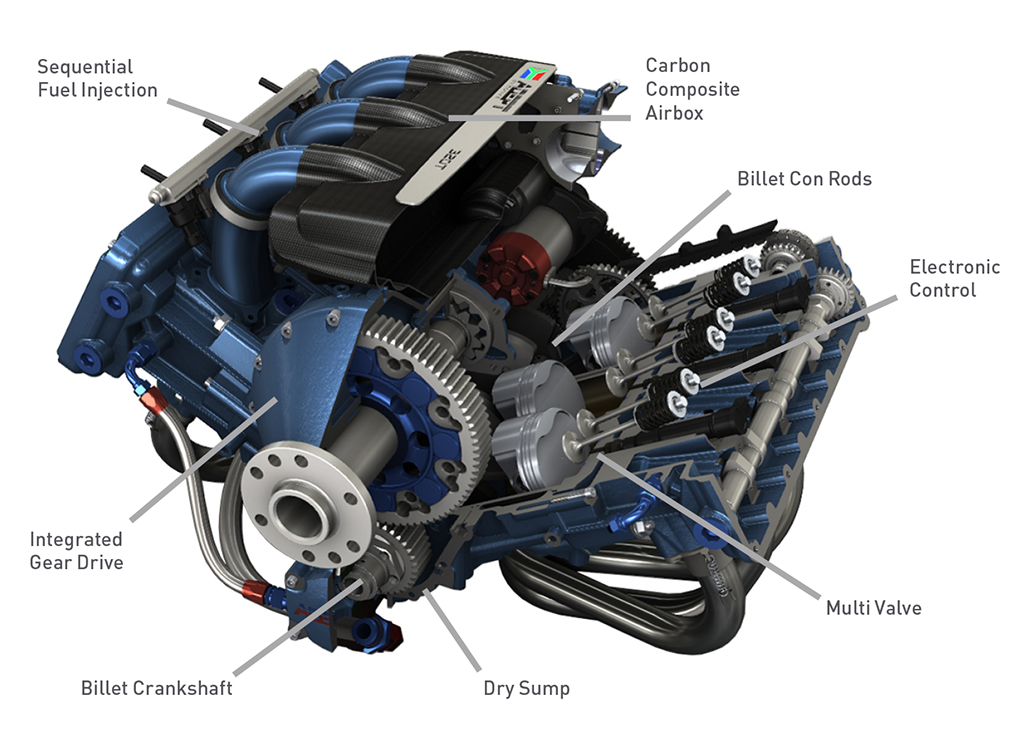

ADEPT’s innovative approach to design and engineering is unique in GA, but would not be considered unusual by anyone familiar with the high-tech world of Motor racing, Moto GP or the Aerospace and Defence. Advanced product development, robust testing and validation, and practical use of technology such as engine design and simulation software all are key to the creation of our superior products.

Design work is done in accordance with the certification requirements of an aviation regulatory approved Design Organization. The use of Rapid Prototyping and Additive Manufacturing has also led to shortened lead times in getting prototype engines built and tested, and advanced Finite Element Analysis, Computational Fluid Dynamics, Non-Destructive Testing processes, and Casting Simulation programs all play their part in ADEPT’s manufacturing and development program.

The ADEPT engine range features a novel and unique (in GA) engine architecture. The 120deg V6 engine layout gives the best solution to the requirements for a lightweight, compact engine with extremely high mechanical strength and integrity, as well as excellent balance, uniform cooling, and the optimum integration of the engine/Propeller Speed Reduction Unit. Fully sequential fuel injection, a unique lubrication system, anti-backlash and gear cush-drive mechanisms in the PSRU all contribute to the smoothest running piston engine in GA.

vs Engine RPM

Compact and Light Weight

Fuel Efficient

Smooth and Responsive

Advanced Manufacturing Processes

Integrated PSRU

Robust Architecture

Liquid Cooled

Avgas / Mogas / Biofuel Compatible

FADEC

Advanced Materials

High Power Density

250N and 360T model variants also available. Contact us for more details.

Advanced Internal Combustion

Compact and Light Weight

Fuel Efficient

Smooth and Responsive

Advanced Manufacturing Processes

Integrated PSRU

Robust Architecture

Liquid Cooled

Avgas / Mogas / Biofuel Compatible

FADEC

Advanced Materials

High Power Density

250N and 360T model variants also available. Contact us for more details.

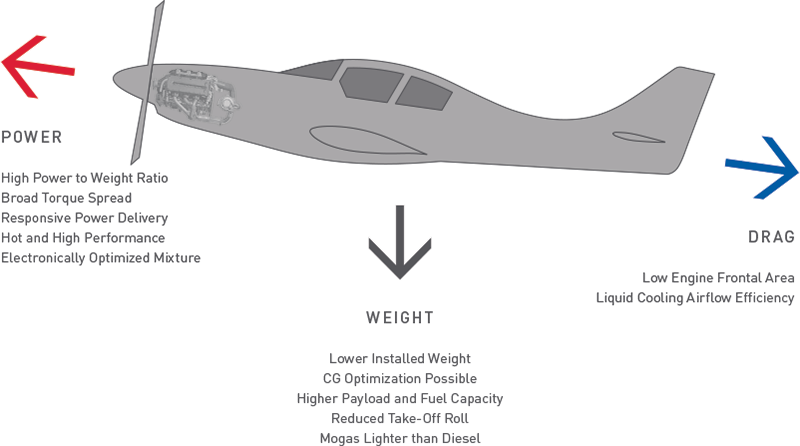

PERFORMANCE ADVANTAGE

= COST ADVANTAGE

Fly Further… for Less

Extremely Fuel Efficient

Extended Range

Lower Cost Fuel –

Unleaded and Ethanol Blends

Low Maintenance Costs

Low Service Part Costs

Extended Maintenance Intervals

Designed for Ease of Maintenance

Increased Payload

Substantial Operating Cost Saving

= SAFETY ADVANTAGE

Robust, Reliable Technology

Extended Range and Performance

Fuel Flexibility and Availability

Excellent Power to Weight Ratio

CG Optimization

Low Pilot Workload

Reduced P Factor

Electronic Mixture Optimization

Enhanced Engine / EFIS interface

Responsive Power on Demand

Smooth Engine Operation

Liquid Cooling for Cabin Heat

No Shock Cooling

No Carb Icing

FIXED WING TRACTOR

COMPETITION AIRCRAFT

FIXED WING PUSHER

AMPHIBIAN PUSHER BUSHPLANE

AMPHIBIAN TWIN

HELICOPTER

FLYING CAR

HYBRID APPLICATION

UNMANNED AIRCRAFT

AG FIXED WING

AG HELICOPTER

STOL APPLICATION

Frequently Asked Questions

Here are some frequently asked questions about our engines. If you have any additional queries, please make contact…

What is the cubic capacity of the engine?

Just less than 3.2 liters (195 Cubic Inches).

What is the bore/stroke ratio?

To keep piston velocity low, the engine has a fairly oversquare bore/stroke ratio (98mm / 3,86” x 70mm / 2,75”) in order to keep piston speed low, as well as fairly short con rods. The short rods give higher piston acceleration which helps in effective filling early on the intake stroke. Narrow and light piston/ring components tolerate high acceleration well.

Is the engine suitable for operation in non-certified helicopter applications?

Whilst the company has initially focussed on fixed-wing applications, the engine is ideal for helicopter operation, and can be optimized to provide high power and torque at constant speed as required in rotary-wing applications. The PSRU also is ideally suited to installation in legacy helicopters which use belt drives to the rotors.

Why is the ADEPT Airmotive not a compression ignition (diesel) engine?

Although diesel has certain advantages with regards to fuel consumption and economy, we don’t believe that compression ignition technology is best suited to GA applications.

Among the reasons for this are:

- Poor relationship between torque and power

- If used at high altitudes Jet-A has to be used as it contains an anti-freeze that diesel fuels do not have

- Compression ignition engines have to be heavier to contain higher bearing loads

- Diesel engines have poor power to weight ratios

- Typical harshness of Diesel engines require complex vibration-isolating solutions

- Harsh firing impulses of Compression ignition engines has a negative effect on reduction gearbox and propeller life

- Satisfactory power generation generally requires high turbo boost with related reliability problems

- Diesel fuel weighs more than gasoline

- We can meet the fuel consumption targets by using an efficient gasoline engine

What aircraft use the ADEPT engines?

ADEPT engines are installed / or are currently in process of being installed in a variety of aircraft including Lancairs, Velocity’s, and some exciting new aircraft in development.

As an example, a 320HP engine is fitted to the all-composite SA Ravin 500 (a South African designed and manufactured aircraft similar to the Piper Comanche). The combination of the ADEPT engine and the Ravin airframe results in one of the finest GA aircraft in the world, with an operating radius of over 1900NM (3500Km) and a 12-hour endurance capability.

ADEPT is working with several Non Type Certified airframe OEMs as well as a wide range of aircraft builders and owners flying aircraft ranging from Super Cubs, Lancairs, Velocitys, RV-10s, and aircraft used in crop spraying and humanitarian operations. In addition, the engine is ideal for legacy aircraft engine replacements once certification is obtained.

What advantages does the ADEPT range of engines have over traditional piston engines?

The ADEPT motor utilizes best-practice current engine technology and is therefore extremely economical and reliable. The ADEPT motor offers competitive acquisition costs and affordable operating and maintenance costs.

What is the expected TBO of the ADEPT engine?

The engine has been designed with a targeted TBO in excess of 2000 hours. Our TBO projections are being confirmed during our monitored flight programme.

How does the adept engine achieve such low operating costs?

The ADEPT engine is extremely fuel-efficient, and runs on Autogas/Mogas that is generally far less expensive than Avgas. ADEPT engines are also designed for ease of maintenance, and utilize readily available, modern service components, with far lower costs than traditional aviation service parts. Due to the modern design of the engine, service intervals are also extended in relation to traditional aviation engines.

What is the advantage of a 120° V6 layout?

It is a compact design offering high efficiencies, lightweight, low vibration levels and high structural integrity leading to long engine life.

Does the ADEPT motor rev higher than existing engines – and does this not lead to rapid engine wear?

Current technology gasoline engines are most efficient at higher RPM than the RPM range at which the traditional legacy aviation engines usually operate. The ADEPT engine’s average piston speed is lower than that of conventional GA engines due to the optimum bore/stroke ratio used. The low mass of reciprocating parts also reduces engine wear.

The ADEPT engine uses a PSRU – are these units not a potential source of problems?

The ADEPT PSRU is a robust and thoroughly engineered unit. It is an integral part of the engine structure. The PSRU reduction ratio has been selected to provide low noise and an absence of annoying and dangerous harmonics. Robust gear forms, and the use of a combination of extremely robust roller bearings for radial shaft support, and taper roller bearings for both pusher and tractor thrust loads ensure reliability and durability. The unit also incorporates a gear cush-drive to protect the rest of the engine from prop strikes.

Production Slots Available

PRESS RELEASE

ADEPT Propulsion Technologies Announces Strategic Commercial Agreement with RapidSky LTD at AirVenture 2024…